Hunting Season is Here. Should You Process Venison?

It is hunting season, and many small lockers take the opportunity to shift the business model to processing venison. First a few reminders on food safety when processing deer…

- Focus only on venison when generating the boneless trim. Don’t try to do multiple species since deer can carry other pathogens.

- Once you have the deer trim, then you can introduce pork or beef as you make snack sticks, grinds, or possibly a deer bacon with added pork [see below]!

- Take care in de-hiding. Don’t contaminate the clean interior with what was on the outside (hair, soil, waste, etc.)

- Manage temperature of the carcass and your cooler. Chill quickly.

Now on to economics and making a profit during venison processing season. Many of your customers likely want jerky. And some will complain at the amount of finished product they receive due to the huge yield loss when dehydrating meat for jerky. Of course they want the backstrap (tenderloin) as is, but what if you can make more whole muscle type product!?

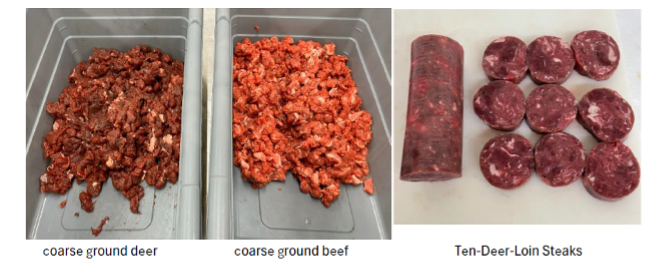

There is a functional ingredient called sodium alginate that allows you to make whole muscle processed meats from quality trim. It is sold as a blend with other key ingredients, so it is a 1-stop shop for the Processor. Here are a couple pictures to illustrate:

Deer meat, and beef chuck roll, were each ground through a kidney plate, mixed with water and the alginate blend, and then stuffed into casings. The product was then placed in a cooler overnight and sliced into “Ten-Deer-Loin” steaks. Notice the “marbling” from the added beef! This product can be ground, mixed and stuffed into its final package in 1 hour! It typically would take 10 manhours to process this amount of meat into jerky. Easier to process, and you can make more money!

Here is a spreadsheet to illustrate. The Processor has been given 40#’s of deer meat. They can make jerky, snack sticks with added pork, or Ten-Deer-Loin steaks with added beef.

Ten-Deer-Loin Economics

Producing jerky from the 40#’s of deer meat resulted in a net profit of ~$104. Making snack sticks with added pork bumped this up to ~$111. Producing Ten-Deer-Loin steaks with added beef, water and alginate blend delivered ~$512 in net profit! This technology provides a huge opportunity to increase profits during deer season, and your happy customers are eating steak! At this point you can afford to GIVE them some beef jerky and/or snack sticks, so that they have a full variety of processed meats to enjoy.

Another process method has generated a lot of interest too. That is taking the coarse ground deer meat, adding coarse ground pork butts, and making a whole muscle deer bacon. Once you mix and form the product overnight, you can now inject a brine solution or do a dry cure rub. The product will have a whole muscle bite whereas most deer bacon is basically a sausage strip.

You can incorporate lots of different flavor profiles, much like regular pork bacon. Be creative and your customers will keep coming back.

If this is intriguing, contact the folks at TheMeatLocker.org, and they can tell you more.

David Hull, Ph.D.

Technical Sales Director-Dickson Industries; Owner-Costout LLC